The materials science field is experiencing a breakthrough with the development of a revolutionary color-changing organogel that can stretch to 46 times its original size while possessing remarkable self-healing capabilities. This innovative material, developed by researchers in Taiwan, represents a significant leap forward in smart materials technology with profound implications for flexible electronics and adaptive systems.

Unprecedented Material Properties Drive Innovation

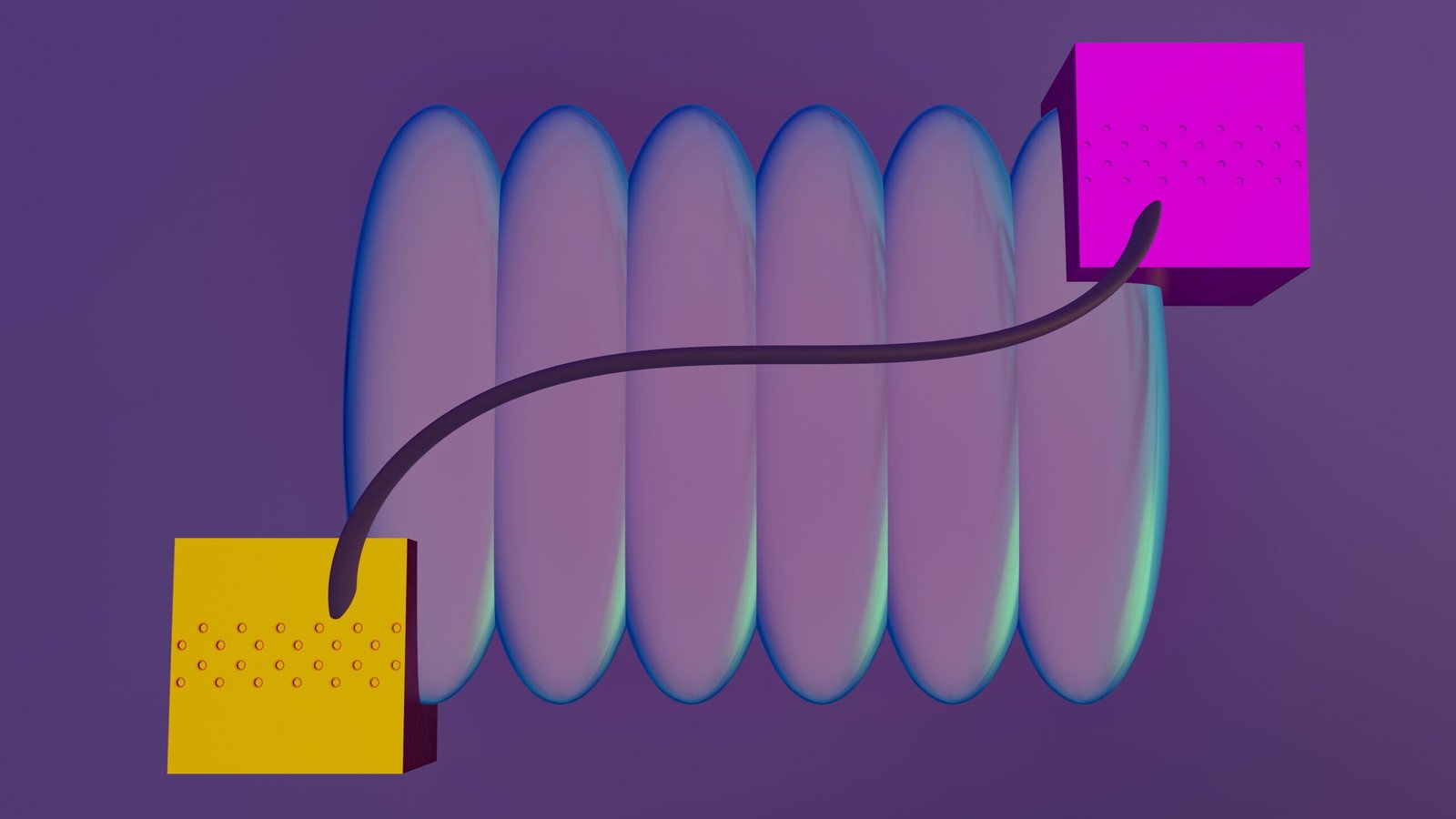

This groundbreaking organogel is built on a sophisticated polyurethane (PU) matrix that integrates covalently linked cellulose nanocrystals (CNCs) with modified mechanically interlocked molecules (MIMs). This unique molecular architecture enables the material to achieve extraordinary stretchability—reaching 4,600% of its original length—while maintaining the ability to autonomously repair damage and recover over 90% of its original properties within minutes. These characteristics make it particularly valuable for applications requiring exceptional durability and adaptability, including next-generation wearable devices and advanced robotics systems.

The Mechanochromic Mechanism Explained

The organogel’s dynamic color-changing capability stems from sophisticated molecular interactions between MIMs and embedded mechanophores throughout its structure. Under mechanical stress, the material transitions from orange to blue, creating a real-time visual indicator of structural changes or potential damage. The integration of fluorescent compounds like DPAC (diphenylanthracene carboxylate) amplifies this responsive behavior, positioning the material as a promising candidate for smart sensing applications and sophisticated anti-counterfeiting technologies.

Transformative Applications and Technical Hurdles

The material’s unique combination of properties opens new possibilities across multiple technological domains. Potential applications span from electronic skin interfaces and soft robotic components to adaptive camouflage systems and responsive architectural materials. However, significant engineering challenges remain, particularly in developing scalable manufacturing processes that preserve the delicate balance between the material’s stretchability, self-healing capacity, and mechanochromic response. Maintaining consistent performance across large-scale production while controlling costs presents additional obstacles for commercial viability.

“This organogel represents a significant leap forward in the field of smart materials, offering a versatile platform for future technological innovations,” said a researcher involved in the study.

Key Breakthrough Characteristics

- Achieves exceptional stretchability up to 4,600% of original dimensions with rapid self-healing in under 10 minutes

- Provides real-time mechanochromic feedback through color transitions that indicate structural stress and damage

- Enables diverse applications from flexible electronics and soft robotics to advanced sensing and security systems

Future Outlook and Commercial Potential

While this organogel technology shows tremendous promise, its path to widespread adoption depends on overcoming manufacturing scalability challenges and optimizing long-term durability under real-world conditions. The material’s unique tri-functional capabilities—extreme stretchability, autonomous healing, and stress-responsive color changes—position it as a cornerstone technology for the next generation of adaptive materials. As research teams continue refining the synthesis process and exploring new applications, these smart organogels could soon transition from laboratory curiosities to commercially viable solutions that transform how we design responsive technologies.